Congratulations on your BaseCore HD geocell purchase! You’ve made an excellent choice for creating a durable, professional-quality driveway or parking pad. Unlike traditional options that require professional installation or lengthy curing times, your geocell system will provide immediate stability while offering superior drainage and load distribution—perfect for everyday vehicles and heavier loads like RVs or boats.

This step-by-step guide will walk you through the entire installation process, breaking it down into five manageable steps that any DIY enthusiast can tackle over a weekend. Your new driveway will provide decades of reliable service with minimal maintenance, all while looking great and preventing common issues like rutting, erosion, and puddles.

Haven’t purchased your geocell yet? Check out our selection of BaseCore HD products to find the perfect fit for your project.

What You’ll Need Before Starting

Before diving into installation, gather these essentials to ensure a smooth process:

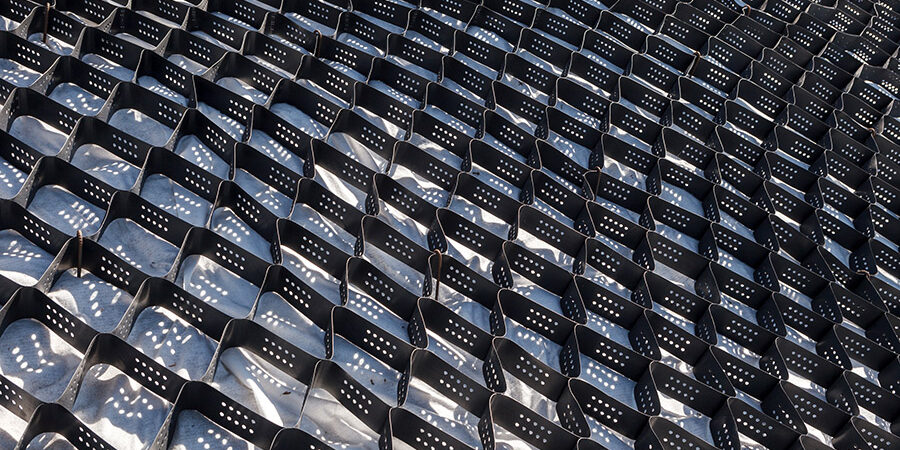

- Your BaseCore HD geocell panels: These expandable honeycomb-like grids form the foundation of your project

- Geotextile fabric: Creates a crucial barrier that prevents weed growth and enhances stability

- Rebar stakes or J-hooks: For securing your panels (some are typically included with your BaseCore purchase)

- Connector clips: To join multiple panels seamlessly (usually included with your panels)

- Infill material: Angular crushed gravel is highly recommended (you’ll need enough for 2-3 inches above cell height)

- Basic tools:

- Measuring tape

- Utility knife

- Hammer

- Rake

- Plate compactor (available at most equipment rental stores)

- Shovel or small excavator for site preparation

- Level or string line

- Work gloves

A typical residential driveway or RV pad project (approximately 20′ x 20′) will require:

- 4-6 BaseCore HD panels (depending on the panel size purchased)

- 1 roll of geotextile fabric

- 16-24 stakes (additional beyond what comes with your panels)

- Approximately 7-10 tons of angular gravel (⅜”-¾” recommended)

With proper planning, most installations can be completed in a single weekend, transforming your property while adding significant value and functionality.

Missing any supplies? Visit our accessories page to complete your toolkit before starting.

The 5-Step BaseCore HD Installation Process

Step 1: Prepare Your Site

Proper site preparation is the foundation of a successful geocell installation. This crucial first step ensures your finished driveway or parking pad will remain level and perform optimally for years to come.

- Mark your installation area: Use stakes and string to outline the exact dimensions of your project.

- Clear the site thoroughly: Remove all vegetation, rocks, and debris from the marked area. For existing driveways, remove old materials completely.

- Excavate to the proper depth: Dig down approximately 3-4 inches from your desired final surface height. This creates space for your geocell system and infill material while keeping the finished surface level with surrounding areas.

- Level the base: Use a rake and hand tamper or plate compactor to create a flat, level base. Pay special attention to eliminating high spots and filling low areas.

- Consider drainage patterns: Ensure the base has a slight slope (approximately 1-2%) away from buildings to promote proper water drainage.

- Create borders (optional): If desired, install edging material like pressure-treated lumber, metal edging, or decorative stone to create clean boundaries and contain your infill material.

Pro tip: Take “before” photos of your project area. Not only will this provide satisfaction when comparing to your finished project, but it’s helpful to document the starting conditions of larger installations.

Estimated time: 2-4 hours for a standard driveway section (depending on existing conditions and project size)

Already preparing your site and realized you need more geocell panels? Order additional BaseCore HD panels here with expedited shipping options available.

Step 2: Lay the Geotextile Fabric

Geotextile fabric plays a crucial role in your driveway’s long-term performance. This specialized material creates a separation layer between your geocell system and the soil beneath, providing these important benefits:

- Prevents weeds from growing up through your driveway

- Stops soil from mixing with your expensive gravel infill

- Enhances load distribution across the installation area

- Improves drainage while preventing erosion

Here’s how to properly install your geotextile fabric:

- Roll out the fabric: Start at one end of your prepared area and roll the fabric across the entire surface. The fabric should extend slightly beyond your planned geocell installation on all sides.

- Overlap seams properly: If using multiple pieces of fabric, ensure they overlap by 8-12 inches at all seams. This prevents soil migration between fabric sections.

- Eliminate wrinkles and folds: Pull the fabric taut as you lay it to eliminate any wrinkles or folds that could create weak points.

- Secure the fabric: Use landscape pins or small stakes to anchor the fabric at the edges and seams. Place pins approximately every 2-3 feet around the perimeter and at each overlap.

- Trim excess (optional): You can either trim excess fabric now or wait until after the geocell installation is complete. If trimming now, leave at least 6 inches of excess around all edges.

Pro tip: On particularly soft ground, consider using a heavier-duty geotextile fabric or even doubling up for extra stability.

Estimated time: 30-60 minutes for a standard installation

Need quality geotextile fabric? Our premium landscape fabric is specifically selected to complement BaseCore HD installations.

Step 3: Position and Expand Your Geocell

Now comes the exciting part—transforming your compact BaseCore HD panels into a full cellular containment system. This expandable design is what makes geocell technology so innovative and effective at distributing weight and preventing shifting.

- Position your first panel: Place the first geocell panel at one end of your prepared area. The collapsed panel should be positioned so it will expand in the direction of your installation.

- Secure the starting edge: Drive stakes through the outer cells of the unexpanded panel to anchor it in place. This creates a fixed point from which to expand the panel.

- Expand the panel: With the first edge secured, pull the opposite end to fully expand the panel. The honeycomb cells will open to their full size. This typically works best with two people—one to hold the secured end and another to pull.

- Check alignment: Ensure the panel is square with your planned area and aligns with any borders or adjacent structures.

- Trim if necessary: If the expanded panel extends beyond your desired area, use a utility knife to cut cells along the perimeter. Always wear gloves when cutting the material.

- Connect multiple panels: For larger projects requiring multiple panels:

- Position panels so their cell walls align

- Use the BaseCore connector clips to join them at multiple points along the seam

- Secure these connection points with additional stakes for maximum stability

Pro tip: On windy days, have extra stakes on hand to temporarily secure sections of the geocell as you work. This prevents the frustration of having partially expanded sections collapse before they’re filled.

Estimated time: 1-2 hours depending on project size

Planning a larger project? Our bulk panel packages include extra connectors and stakes at a discounted rate.

Step 4: Secure Your Geocell System

Properly anchoring your geocell is critical for long-term performance. This step creates a stable foundation that will resist shifting and movement, even under heavy loads like RVs or during freeze-thaw cycles.

- Stake placement planning: Determine optimal stake locations—focus on:

- Panel edges (every 3-4 feet)

- Panel corners (critical anchor points)

- Panel connection points

- Areas that will bear the most weight

- Any location where the geocell might tend to lift

- Drive the stakes: Using a hammer or mallet, drive rebar stakes or J-hooks through the geocell walls. The stakes should:

- Penetrate completely through the geocell

- Enter the ground beneath by at least 6-8 inches

- Sit flush or slightly below the top of the cell walls

- Check for proper expansion: Before completing your staking, verify that:

- All cells are fully opened to their hexagonal shape

- No cells are collapsed or pinched

- The overall panel maintains its intended dimensions

- Final alignment check: Step back and verify the entire installation is:

- Level across the surface

- Properly aligned with adjacent structures

- Following your planned perimeter

- Securely attached at all panel connection points

- Address any issues: If you notice any problems:

- Collapsed sections: Remove nearby stakes, re-expand, and re-stake

- Misalignment: Adjust before filling by removing and repositioning stakes

- Lifting edges: Add additional stakes where needed

Pro tip: Use more stakes than you think you need, especially for load-bearing areas like tire paths and turning areas. The small additional cost of extra stakes is worth the enhanced stability they provide.

Estimated time: About 1 hour for a standard installation

Need additional stakes? Our heavy-duty J-hooks provide superior anchoring power in all soil types.

Step 5: Add and Compact Your Infill Material

The final step transforms your expanded geocell framework into a solid, durable surface ready for immediate use. Proper infill selection and compaction are crucial for maximizing your driveway’s load-bearing capacity and longevity.

- Select the right infill material: Angular crushed gravel (⅜”-¾”) is ideal because:

- The angular edges lock together for superior stability

- It provides excellent drainage properties

- It resists migration and compacts efficiently

- It creates an attractive finished appearance

- Begin filling the cells:

- Start at one end and work systematically across the installation

- Pour or shovel material to fill each cell completely

- Distribute evenly, avoiding large piles that might distort the cell structure

- Fill to approximately 1 inch above the cell walls initially

- Level the infill:

- Use a rake to spread the material evenly across all cells

- Ensure consistent filling with no empty or overfilled areas

- Pay special attention to the edges and connection points between panels

- Initial compaction:

- Use a plate compactor to make an initial pass over the filled cells

- Work in a systematic pattern, overlapping each pass slightly

- Start from the edges and work toward the center

- Watch for any cells that become exposed during compaction

- Add additional infill as needed:

- After initial compaction, add more material to any low spots

- Build up to approximately 2 inches above the cell walls

- This extra material ensures complete cell coverage after final compaction

- Final compaction:

- Make multiple passes with the compactor in different directions

- Pay extra attention to high-traffic areas like tire paths

- The surface should feel firm and stable when walked on

- Ensure the finished height blends smoothly with adjacent surfaces

Pro tip: Consider using a different color or size of gravel for visual interest, such as a border of contrasting material around the perimeter of your driveway.

Estimated time: 2-4 hours depending on project size

Need quality angular gravel delivered? Ask about our local delivery partnerships for recommended suppliers in your area.

Maintaining Your BaseCore HD Driveway or Parking Pad

One of the major advantages of your new BaseCore HD installation is its minimal maintenance requirements compared to traditional surfaces. However, a few simple practices will keep it performing beautifully for decades.

Routine Maintenance (Every 6-12 months)

- Visual inspection: Check for any areas where cells may have become exposed or infill has migrated

- Top-up infill: Add additional gravel to any low spots that develop over time

- Edge maintenance: Ensure borders remain intact and continue to contain the infill material

- Drainage check: After heavy rain, verify that water drains properly with no puddling

Seasonal Considerations

- Winter care: Your geocell driveway can be plowed or shoveled like any other surface. The cellular structure prevents plow damage that often occurs with asphalt.

- Spring renewal: After winter, inspect for any gravel displacement from snow removal and replenish as needed.

- Weed management: Though the geotextile barrier blocks most weeds, occasional spot-treatment may be needed along edges.

Long-Term Performance

With proper installation and minimal maintenance, your BaseCore HD driveway or parking pad is designed to perform for 60+ years. The high-density polyethylene material resists:

- UV degradation

- Freeze-thaw damage

- Chemical exposure

- Structural fatigue even under repeated heavy loads

Pro tip: Keep a small supply of your infill material on hand for occasional touch-ups, especially during the first year as the system fully settles.

Looking for complementary landscaping ideas around your new driveway? Check out our project inspiration gallery for beautiful integrations with existing landscapes.

Enjoy Your New BaseCore HD Driveway for Decades to Come

Congratulations on completing your BaseCore HD installation! You’ve created a professionally engineered driveway or parking pad that combines the best aspects of traditional surfaces—the strength of concrete with the drainage of gravel—all at a fraction of the cost and installation effort.

Your new surface offers:

- Immediate usability with no curing time

- Excellent drainage to prevent puddles and ice formation

- Superior load distribution for vehicles of all sizes

- Minimal maintenance requirements

- An environmentally friendly pervious surface

- Long-term durability (60+ years of performance)

As you enjoy your new driveway, remember that the BaseCore HD system is versatile enough for many other applications around your property. Many customers who start with a driveway project soon discover additional uses for this innovative system, from garden pathways to equipment pads, shed foundations, and more.

We’d love to see your finished project! Share photos on social media and tag us, or send them directly to our customer gallery. Your success can inspire other DIY enthusiasts to achieve similar results.

Ready for your next project? Explore our complete collection of BaseCore solutions for every area of your property.

This installation guide is based on best practices for typical residential installations. For commercial applications or specialized circumstances, please consult with our technical team. BaseCore HD is a registered trademark and all product specifications are subject to change. Always check local codes and regulations before beginning your installation.